The mystery of the Wurlitzer 200a ornamental speaker screws

Spoiler alert: we solved it (with the help of the documents)

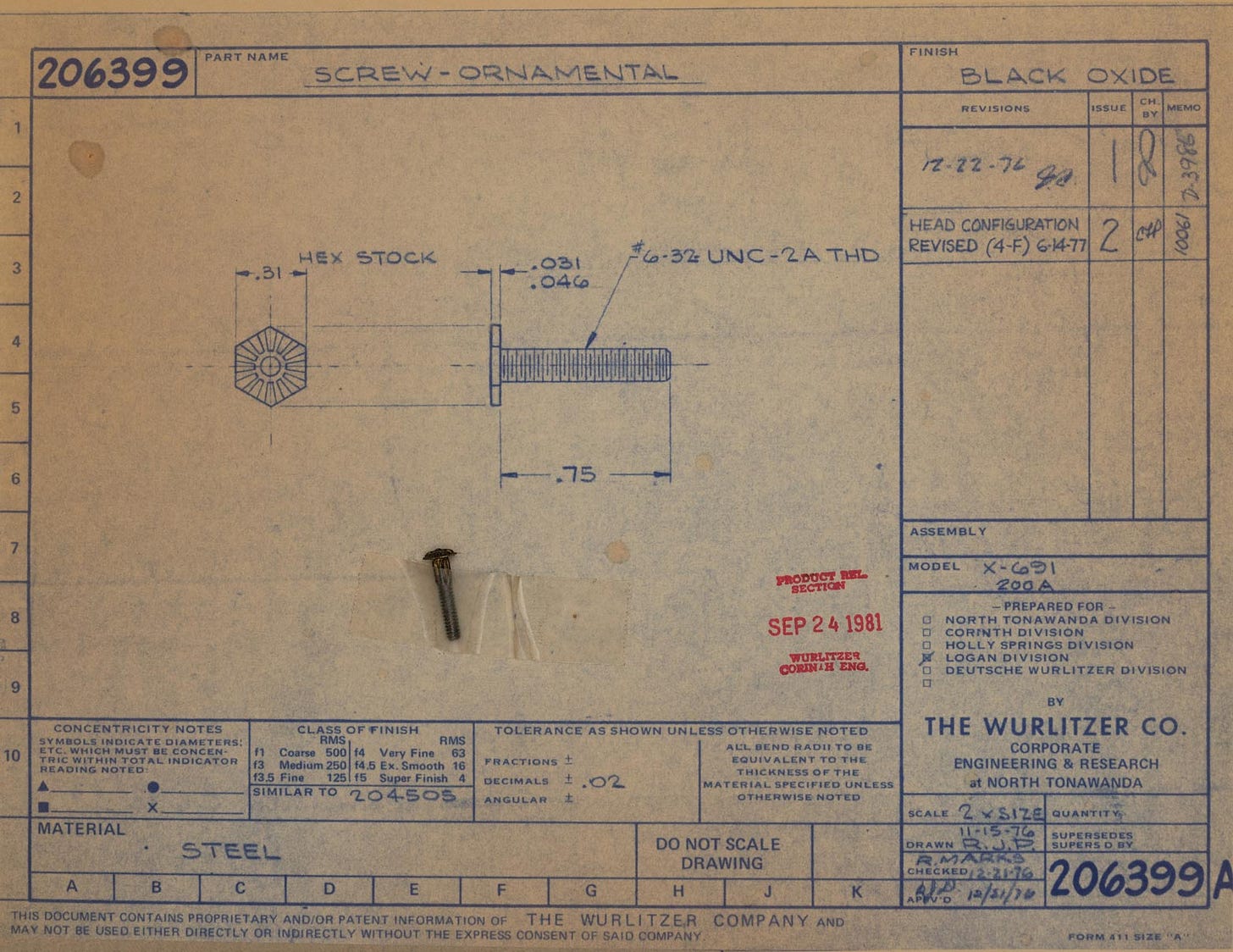

I love the design details of Wurlitzer keyboards, and one of my favorites is the screws. Vintage screws are so much more stylish than new ones. Even the utilitarian screws have a little elegance. There’s the golden screws that hold down the lid on 140-series Wurlitzers; the reed screws with the little R embossed on top. But the fanciest Wurlitzer screws are, arguably, the flowerhead 200a speaker screws. (The 700 speaker screws are also pretty cool.)

The 200a speaker is mounted using flowerhead screws. Flowerhead screws used to be very common, back in the days when speakers were attached to wooden baffles using visible screws. Because they were visible, and because it was the late 1960s, the screw heads had a little flower design. (Back then, people were not afraid of a little gratuitous ornamentation. Today, design is more likely to be smooth and featureless, and no company selling products for mass consumption would allow flowers on the hardware unless they really had a good reason. They don’t make things like they used to!!)

We used to buy replacement 200a speaker screws from the Wurlitzer warehouse. Like everything the warehouse sold, their flowerhead screws were certainly vintage. However, they were not original.

The original Wurlitzer 200a screws, which we found time and again on 200a keyboards, had flower petals arranged in a hex shape. The warehouse screws had a similar flower, but they were round. We didn’t mind, because the screws were definitely vintage, and there was authenticity in the fact that the warehouse had been selling them for so long. But we always wondered why the warehouse screws were different, where they came from, and why they seemed to have so many.

We found the answers in the documents.

HOW THE WURLY DRAWINGS WORK

The vast majority of the documents are engineering drawings. (We also got a few service manuals.) Of these drawings, there are two categories. The first category includes all drawings that were just stuffed into the drawers without folders of any kind. These drawings were stored upright by the sheer fact that the drawer was so overstuffed that none of the papers inside had any room to slide around. Like a complete deck of cards in its box.

The second category of papers were stored in hanging file folders. These drawers were also pretty overstuffed, but the folders were capable of hanging freely, so these papers are in somewhat better shape than the others.

There doesn’t seem to be that much difference between the two categories, as far as the content of the drawings. However, the ones that were stored in hanging file folders were often filed with several secondary documents. There were three main kinds:

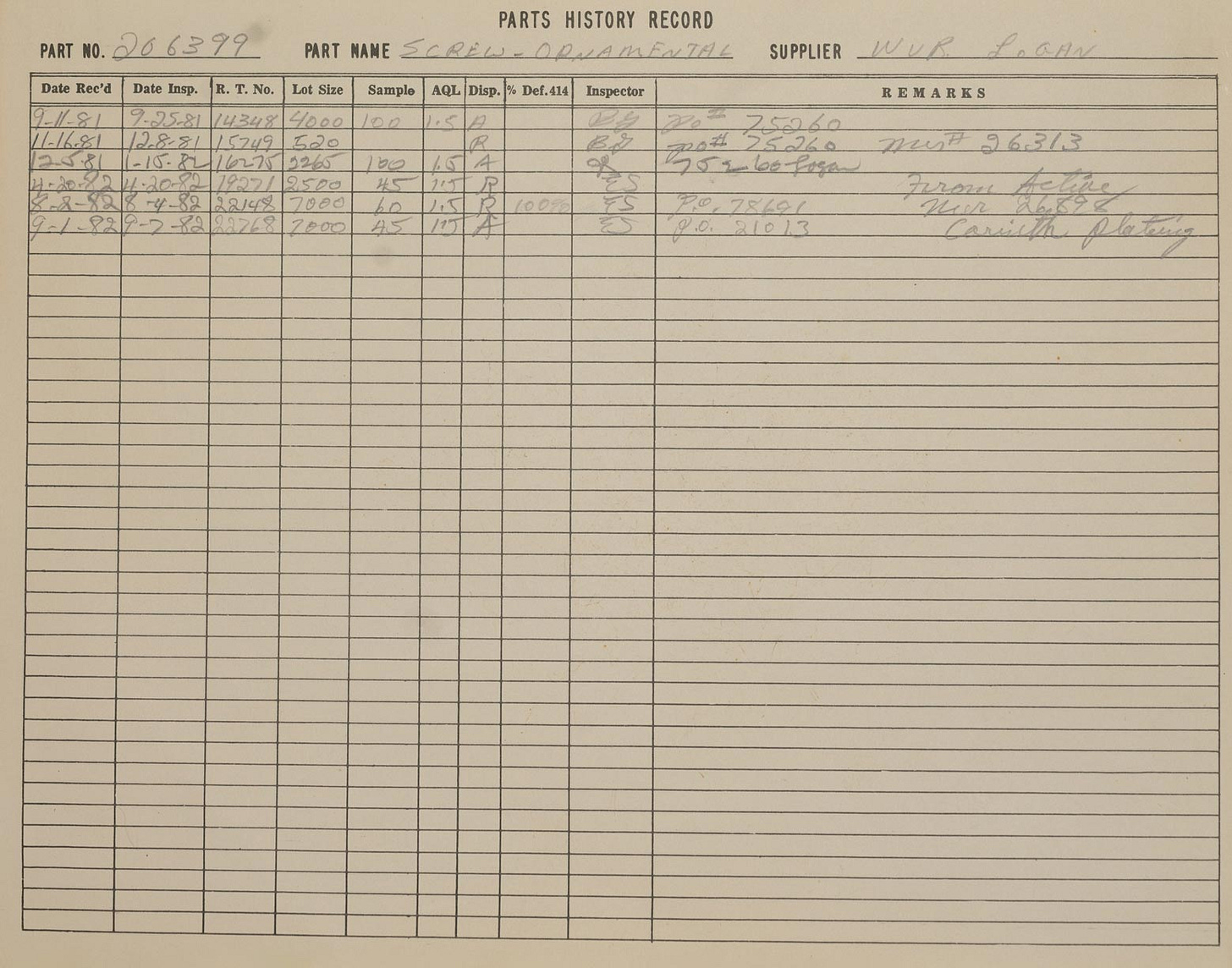

Parts History Records. This is a chart that lists every time the Wurlitzer Co. ordered the part depicted in the drawing. It includes the date the parts were ordered, the number of parts that were ordered, and the number of parts that were inspected by the Quality Department.

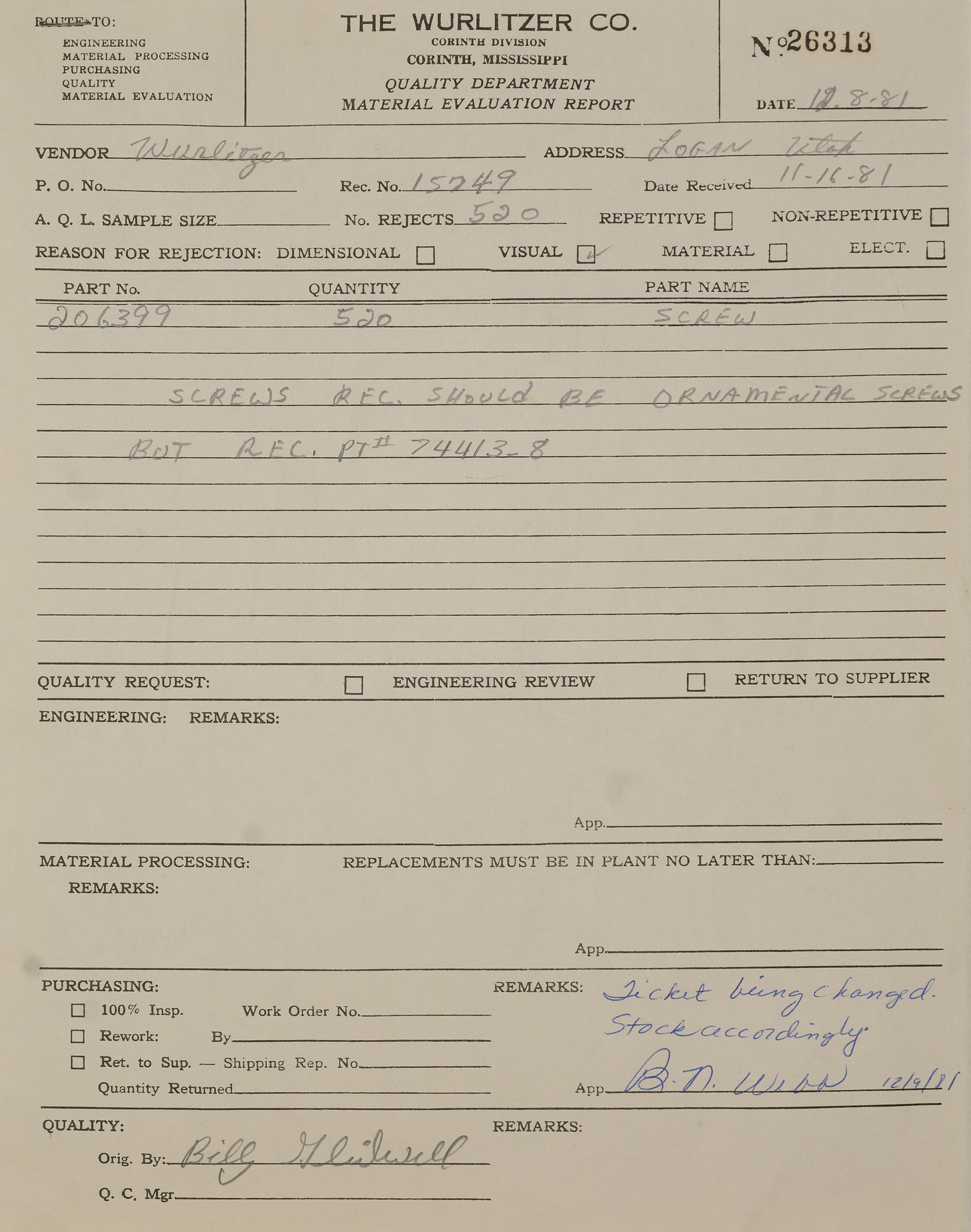

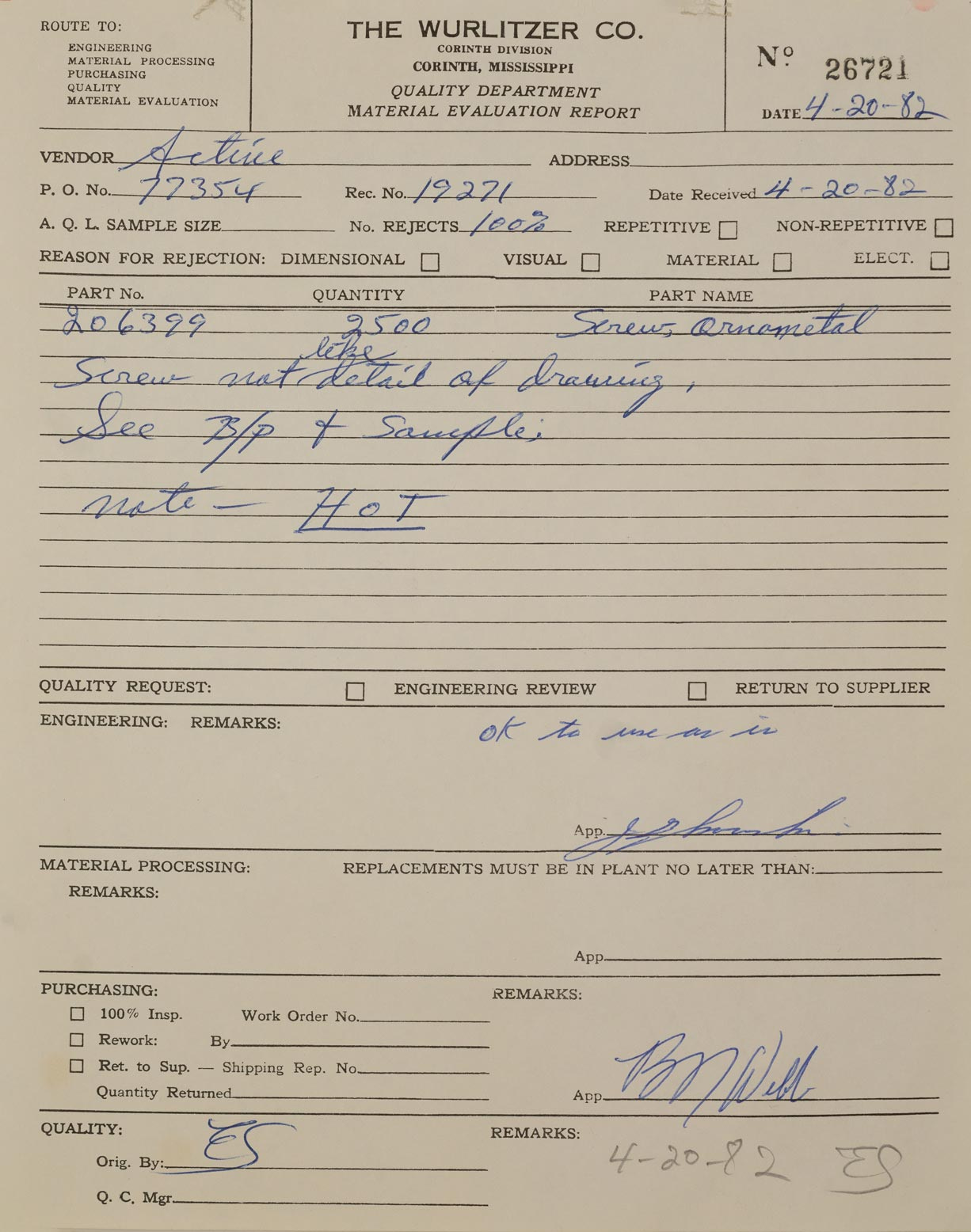

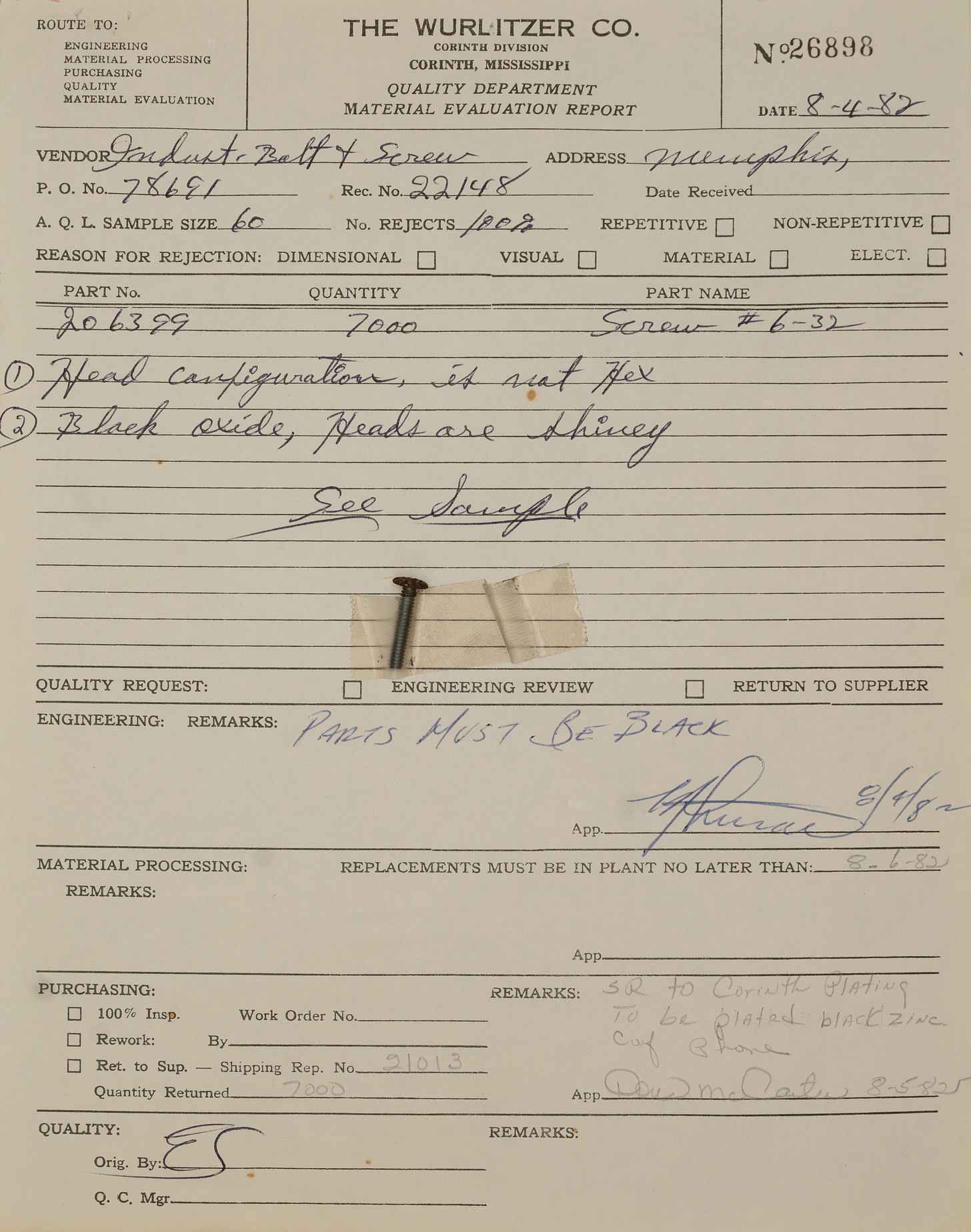

Quality Department Material Evaluation Reports. If, after inspection, the Quality Department rejected some or all of the parts shipment, they wrote up a Material Evaluation Report. In the report, they explain the reason why the parts did not meet Wurlitzer’s standards. This report is then sent to the Engineering Department, the Material Processing Department, and/or the Purchasing Department. A representative from the departments will write a little note regarding next steps. For instance, sometimes the Engineering Department will acknowledge that the parts fall short of prior standards, but they’ll give the okay for the parts to be used anyway.

Correspondence. If someone at Wurlitzer is really upset that the parts that they ordered are incorrect, they will sometimes write a letter to the original manufacturer complaining about the mistake. If the manufacturer is a big company, like RCA, the tone of the letter is conciliatory. If the manufacturer is a smaller, local company, the letter is extremely pointed or even a little threatening. The manufacturer will either respond A) by telling Wurlitzer that they’re going to take the parts they receive, and like it, or B) promising Wurlitzer that they’ll never make any mistakes ever again, and begging them not to cancel their contracts.

The more complex the part, the more Quality Department reports are in the file. Transistors, for instance, often come with a lot of paperwork. Washers, capacitors, and decals do not. For the 200a speaker screws, we have three reports—which is a lot, compared to most of the other drawings.

THE FLOWERHEAD SCREW QUALITY REPORTS

The first Quality Report we have is dated December 8, 1981. Here, 520 screws were rejected. The explanation: “Screws rec. should be ornamental but rec. pt # 74413_8.”

Then, the report was passed on to the Purchasing Department. They replied: “Ticket being changed. Stock accordingly.” This is ambiguous, but possibly means that the rejected screws were re-categorized as 74413_8. (I’m not sure which part that is, but I’ll be looking for the drawing in the collection.)

The next Quality Report is dated April 20, 1982. On this occasion, Wurlitzer received 2500 screws, all rejected. The comment reads: “Screw not like detail of drawing. See B/P + sample. Note—HOT.” Below, the report is signed by Engineering with the comment, “ok to use as is.” The report is also signed by Purchasing, without comment. Unfortunately, this report does not indicate what the screws might have looked like.

The third Quality Report, dated August 4, 1982, is the most interesting. Here, Wurlitzer received 7000 speaker screws from Industrial Bolt & Screw in Memphis—all rejects. The comment reads:

(1) Head configuration, is not Hex

(2) Black oxide, Heads are shiney

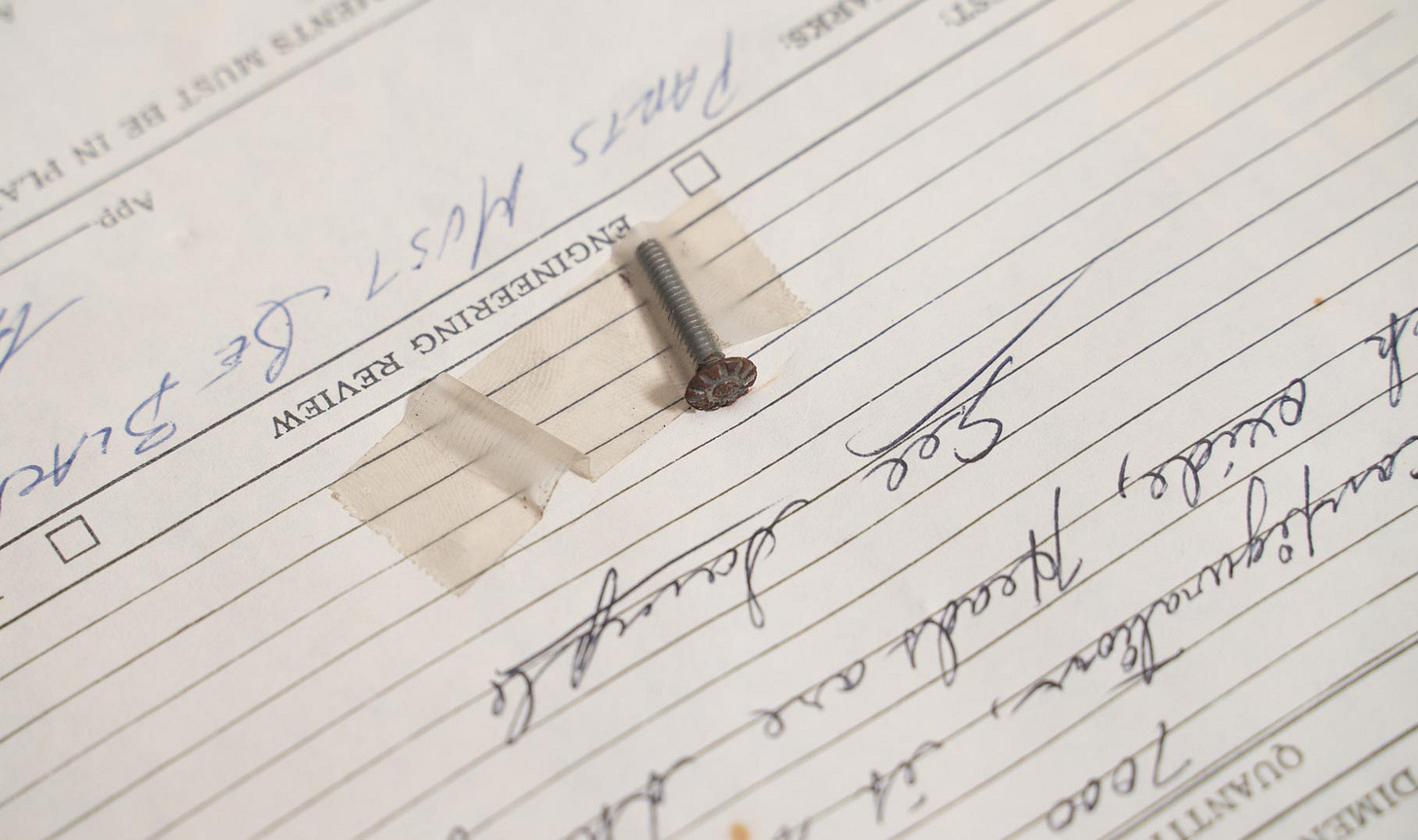

See SampleAND THE SAMPLE IS TAPED TO THE REPORT

THE SAMPLE IS THE WAREHOUSE VERSION OF THE 200A SCREW

EXCEPT IT IS NOT BLACK—IT IS SILVER AND COMPLETELY COVERED IN RUST!!!

Engineering comments on August 4: “PARTS MUST BE BLACK.”

Purchasing comments on August 5: “SR to Corinth Plating to be plated black zinc conf. phone.”

THE MYSTERY OF THE 200A SPEAKER SCREWS—SOLVED!!!

So, with these three Quality Reports, we can basically reconstruct what happened.

Each 200a requires eight ornamental screws for mounting the speaker to the plastic lid. The screws have to be ornamental, because they are visible. They have to be black, so they blend in with the keyboard’s black plastic case. (It’s 1982, so all 200a Wurlitzers are black.)

The screw needs a drawing, because, without a drawing, the part doesn’t exist in the system. (This is an inference—but there are Quality Reports in the collection bemoaning the confusion and inefficiency that results from the lack of an accurate drawing.) The drawing has to depict a specific screw, because that’s the nature of a drawing.

However, nobody really cares what the flower design on the front of the screw looks like. The screw head in the drawing has a hexagonal shape, but it’s too thin to be functional, as a hex head bolt is. It’s just a shape. Nobody is attached to it. Wurlitzer engineers have better things to do than worry about the genus of flower that is depicted on the speaker screws of one of the lowest-priced keyboards in production, at the twilight of its manufacture. They’re focused on the instruments of the future, like the Omni 6000 Keyboard Computer. As long as the 200a screws are black and ornamental, everyone’s ready to call it a day.

But the August 4 screws are not black—they’re just regular, shiny, basic screw color! But that’s okay. The Corinth factory has the facilities to plate screws in black oxide. Problem solved.

By 1982, production of electronic pianos was quickly winding down. Steve Espinola estimates that the last Wurlitzer 200a was assembled around July 1983. It’s possible that some of the 200a Wurlitzers would have received Corinth-plated non-hex speaker screws in the eleven months between August 1982 and July 1983. It’s also possible that Wurlitzer did not have to install any “incorrect” speaker screws in any 200a, because they ended production before they used up their remaining stock of “correct” hex-shaped flowerhead screws. Wurlitzer was a big company, and could certainly afford to restock their parts well before anyone had to scrape the bottom of the bin. Plus, we’ve definitely seen 1983 Wurlitzers with hex screws.

So, with 7000 screws in the batch, there were quite a few left over when Wurlitzer ended production of electronic pianos in 1983. Just a few years later, the Corinth factory shut down entirely—before anyone could devise any new products that might have required 7000 ornamental screws.

We know that the owner of the warehouse was a Wurlitzer employee who purchased all of the leftover electronic piano and organ parts when the factory shut down. This must have included a big box of slightly “incorrect” Wurlitzer speaker screws, plated in black oxide—so many thousands of screws that he was able to sell them to us, forty years after they were produced.

And so, you actually could classify the screws as “original.” The Wurlitzer Company did purchase them, and they did intend to use them in 200a keyboards. They just stopped making electronic pianos before that could happen.

A MYSTERIOUS THIRD TYPE OF SCREW

Aside from the warehouse screw, the only other ornamental screw we’ve ever been able to find in reasonable quantities has a round head embossed with a daisy and some little floating dots. We used to buy this screw from Antique Electronic Supply, but they stopped producing it, and now ornamental screws are basically extinct.

We're not sure where this design came from. We've idly wondered whether it's a classic screw design from some vintage amp we're not familiar with? Or maybe Antique Electronic Supply came up with it themselves—maybe it's just a design that requires simpler tooling? Anyway, we're on the side of the Wurlitzer engineers: if it's black and has a flower on it, we're happy. (Actually, the Antique Electronic Supply screws were silver, but that's close enough. Lacking the plating facilities of the Corinth factory, we paint them.)

So, we were extremely surprised to open up the original hex-shaped flowerhead screw drawing and discover—without explanation or context—the Antique Electronic Supply daisy-style screw, attached to the paper with an old piece of tape. We're not sure how it got there, or what relationship it has to the 200a speaker screws. Maybe, as we find more flowerhead screw drawings, we'll figure it out.

Thank you for subscribing to Keyboard Notes! I hope you enjoyed this article about the Wurlitzer documents. I’ll have more to share as I scan more documents! See you next week!